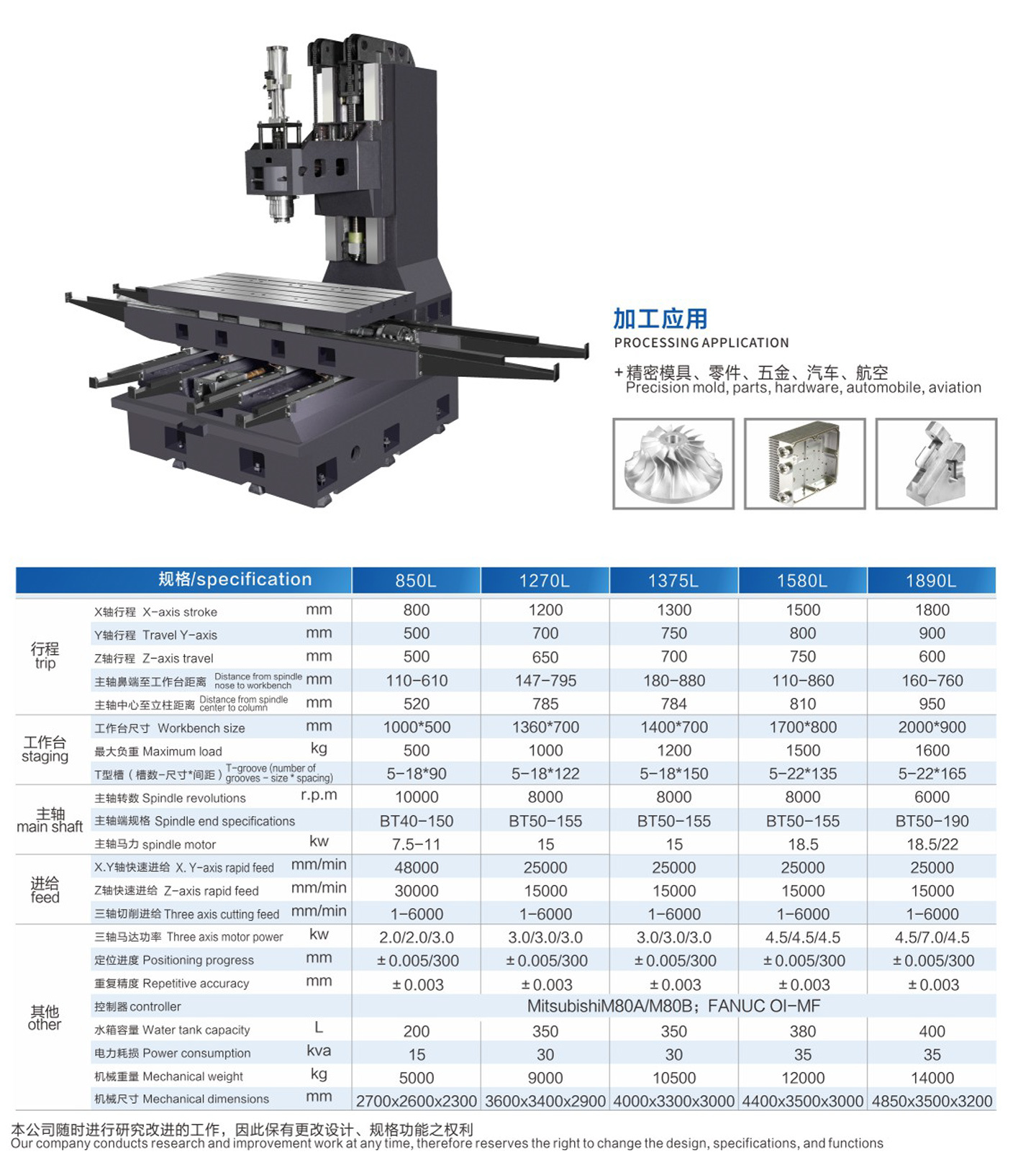

Vertical machining center with two lines and one hard series

Key words:

Vertical machining center with two lines and one hard series

Classification:

Detailed introduction

MACHINE CHARACTERISTICS

Resin sand castings are used in all castings.After two a artificial aging treatments, the castings have good stability, high strength and reliable accuracy.

The spindle is manufactured by shaft is produced by Taiwan's professional matching manufacturer, and the important parts are strengthened, the spindle is ubricated by KLUBRNBU 15 grease and bearings of world-famous grade P4 spindle. Afer the spindle is assem-bled under constant temperature,the spindle needs to be adjusted by computer balance and run-in test,so that the service life of the spindle is long and reliability is high.

The ball screw is pre-tightened with precision twin nuts provided by Taiwan and Japan. The two end bearings are special ball screw bearings with paired combination of imported P4-60 contact angle.

Recommend

Horizontal machining center machine series

High torsion belt spindle design.

Vertical and horizontal integrated composite machine

The combination of gantry moving shaft and horizontal plus can be used as a horizontal machining center alone or as a gantry machining center.

Gantry machining center machine series

The base adopts an integrated casting structure and a closed rectangular structure design.

Five axis linkage gantry machining center

Thanks to the design of the overweight load-bearing body structure,the powerful processing ability can achieve precision machining of heavy cutting.

Product message

Tell us what you need and we'll get in touch with you as soon as possible!

The company provides one-stop services from independent optical machinery, independent outer cover sheet metal, to the entire machine.

Address: No. 5, Yanjing Road, Dongcheng Sub-district Office, Tongliang District, Chongqing

Chengchuan CNC